To help improve the efficiency of your manufacturing and quality control processes using digital transformation, salamanderU has developed a new version of SmartReg, the first patented voice controlled EBR (electronic batch record). This new version can be considered as a Manufacturing Execution System (MES). SmartReg next generation integrates more data management, allows connections through APIs, improves security and manages cloud control.

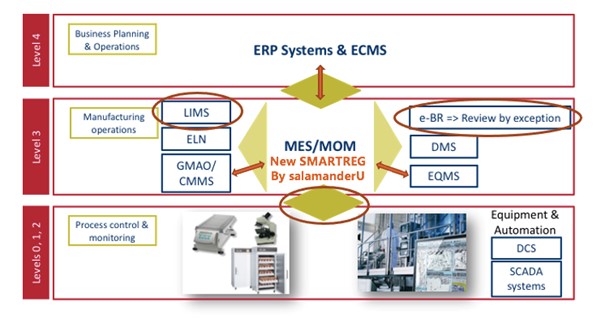

Figure 1: ISA (International Society of Automation) is working together with organizations such as MESA (Manufacturing Enterprise Solutions Association) to establish standards about integrated systems in enterprises. In particular, the ISA-95 standard defines 5 layers in manufacturing operations. It also defines the link between Enterprise Systems and the MES layer: the MES functionality, the database scheme at the MES level and information exchanged between MES and Enterprise Systems.

New features of SmartReg next generation

1. Connection with existing equipment and software

SmartReg next generation provides intelligence through data management in real time. It manages:

- continuous information such as real-time environment monitoring data;

- immediate responses from equipment (for example, result of a weighing);

- delayed responses (for example, QC testing results).

The new version also allows you to control the equipment (for example, starting or stopping a centrifuge or a robot) and provides interface possibilities (APIs for ERPs and LIMS, directories such as LDAP).

Figure 2: SmartReg next generation manages immediate responses from equipment, such as microscope results.

2. Secure password management

We’ve added some safety improvement features, such as:

- the automatic closing of a work session after a pre-defined inactivation period;

- very secure password management;

- the ability to block someone who enters the same incorrect password several times within a defined period of time.

3. Improvement of SmartReg’s existing features for a better user experience

Some examples:

- extra features in the builder module to accelerate MBR creation and allow using robots during manufacturing steps;

- the possibility to run several operations in parallel by several operators. Work units can also be run automatically, without input from operators;

- the possibility to make comments by voice, text or keyboard. These can be made obligatory if necessary, for instance if the value is changed by the operator;

- the possibility to let specific values be clearly highlighted so there’s no need to review the entire report;

- a graphic representation of the data automatically acquired by the integrated instruments;

- the possibility to have the QA (Quality Assurance) module automatically generate digitalized versions of the batch records, has been improved with an extension of the attached file, audio file, etc.

4. Complete integration of all your data for better decision-making

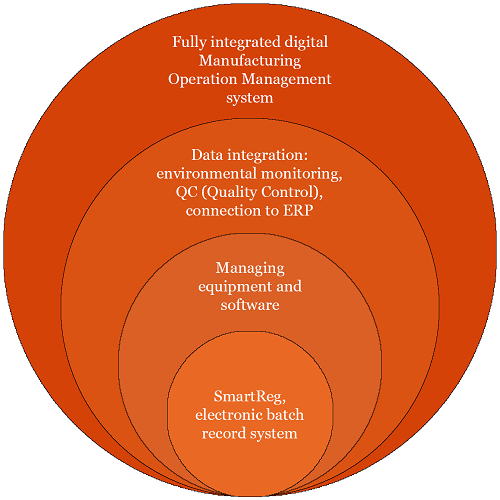

SmartReg next generation is now your Manufacturing Execution System that improves your performance. Our stand-alone electronic batch record system has become a fully digital integrated package that smartly drives your manufacturing and quality control operations.

The real-time integration of the equipment and environmental monitoring data will support you in your on-site decision-making. Moreover, the complete integration with your ERP and LIMS data will allow you to analyze your overall data in order to improve your processes.

Figure 3: SmartReg has evolved from a stand-alone electronic batch record system to a fully digital integrated package that drives your operation processes with new intelligence.